PP or Polypropylene is the hero of this post. This commodity resin has good fatigue resistance – meaning, it can be bent and reversed repeatedly a very high number of times before it fails. This makes PP the best choice to make plastic flip top caps.

Flip Top Caps (FTC) have become a part of our daily life, be it on a shampoo bottle or honey dispenser. We open the flip and it stays in place, out of the way of the product when dispensing. And once done we can flip it back to close the bottle. The hinge – the thin bands joining the cap and the flip, plays a vital role in all of these.

Dead Hinge or Flat hinge

This type of hinge does not have spring action. The flip does not jump into the open or closed position when using the part. A typical dead hinge comprises of a link between the cap body and the flip with a straight thin section allowing it to fold without breaking. Besides closures, this type of hinge is also used in containers, lunch boxes.

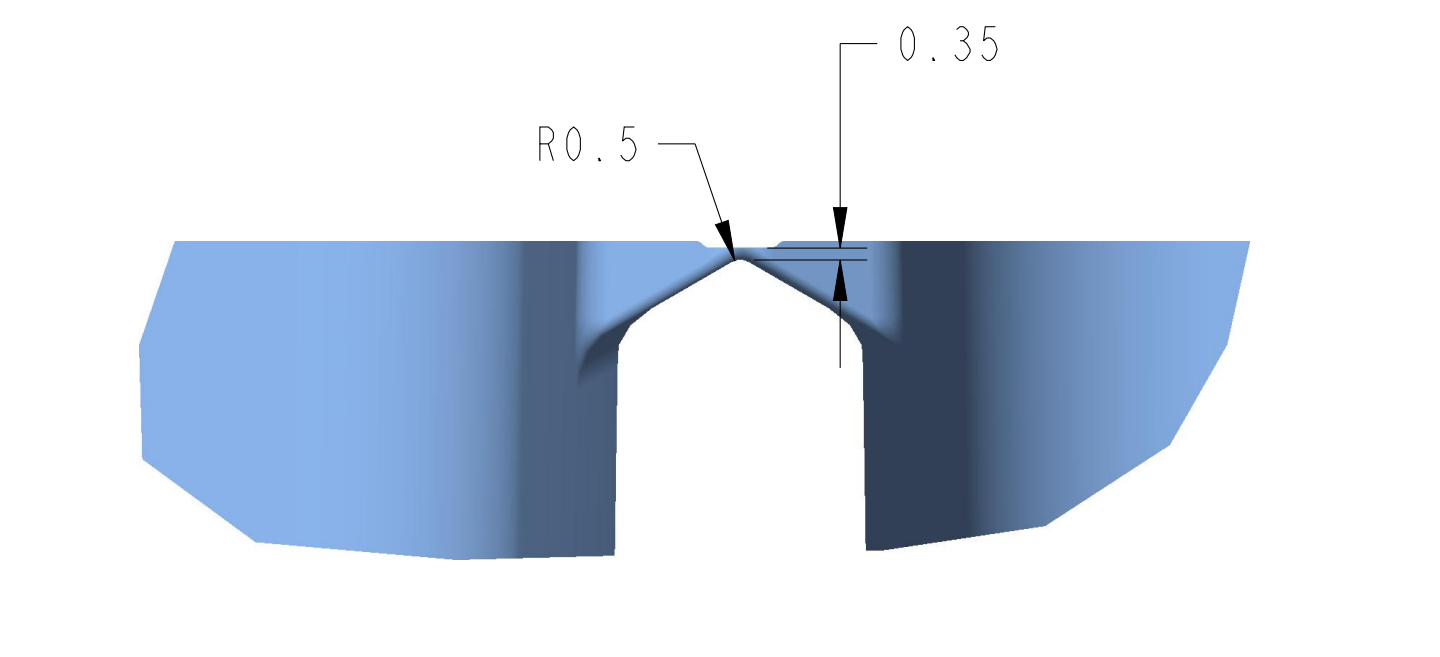

This picture shows a side sectional view of a dead hinge. The thinnest portion is around 0.35mm, and it forms a straight line across the length. This thin straight line defines the axis of rotation, usually called hinge axis.

Butterfly Hinge

Butterfly hinge is probably the most common type of living hinge (the ones with hinge action). The name comes from the fact that they resembles a butterfly when the cap is in closed. Butterfly hinge can be of three types based on the construction.

3-Piece Butterfly Hinge

These has three defined sections. The center part is shaped similar to a Flat hinge and defines the hinge axis. On either side are the tension bands. These bands are usually slightly lower than the hinge axis, so that when closing the bands are under tension load. The bands are also designed slanted down towards the outer edges so that the required tension is achieved.

True Butterfly Hinge

This type of hinge is a continuous band of thin plastic. It does not have a properly defined hinge axis. These are the most clean looking hinge, but due to the lack of a defined hinge axis, they require more expertise and experience to achieve hinge action.

Butterfly Hinge with Notch

These are very similar to the butterfly hinge, but with a section in the middle shaped into a thin straight notch. This defines the imaginary line across which the part folds, also called hinge axis

Band Hinge

Band hinge works a little differently. This option has a spring band at the center of the hinge instead of the tension band. There are two pieces at both sides to crate the hinge axis. The hinge band is thick and stiff, but have thinner portions at the ends where it joins the cap body and the flip. The spring band deforms elastically as the cap is opened and provides the hinge action.

Typically, the spring band is shaped to follow the shape of the cap in closed condition. This type of hinge design is used when the shape of the cap makes it difficult to build the other types. As the shape of the cap defines the hinge design, the designer can play with the width of the bands to control the hinge action.

Bi-injection Hinge design

Bi-color caps serve the dual purpose of providing a premium unique look and to deterrent to counterfeiting. Two different color material are used to form the cap, usually the flip is of a different color to the cap body. Sometimes a portion of the cap is made of different color to the rest of the cap. A process called bi-injection molding is used to create these designs.

To learn more about bi-color molding please click here.